Description

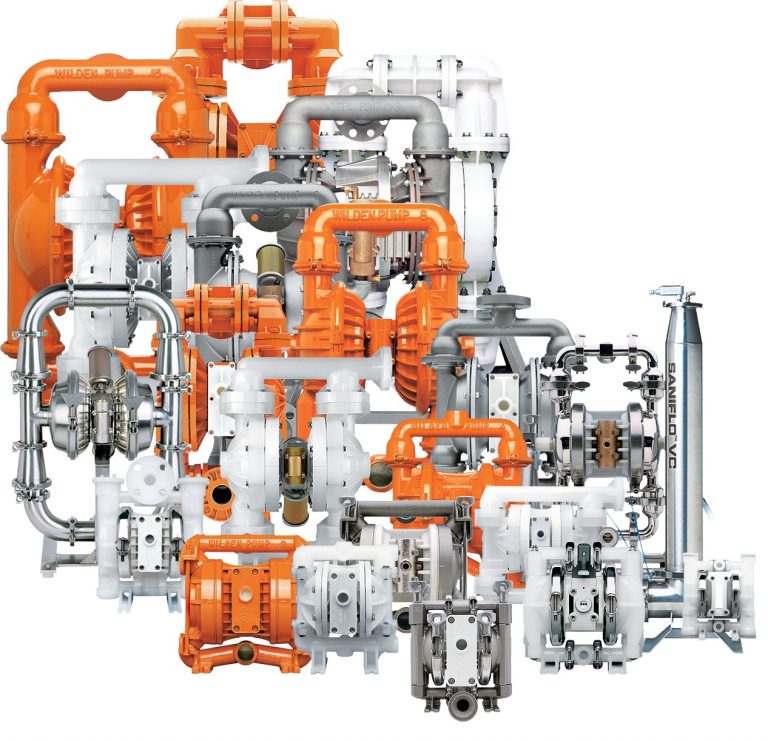

WILDEN PUMPS

The Wilden® family of Air-Operated Double-Diaphragm (AODD) pumps has proven its rugged durability and reliable performance in countless installations since 1955.

Wilden Pump in Pakistan

As the inventor of the Air-Operated Double-Diaphragm (AODD) pump, Wilden remains the trustworthy industry leader by pioneering new innovations while providing unparalleled excellence in customer satisfaction. Wilden has also developed state-of-the-art Air Distribution Systems (ADS) that significantly increase positive displacement pump productivity by reducing air consumption and maintenance for the most energy-efficient AODD pump operation possible.

Wilden has an Air-Operated Double-Diaphragm (AODD) pump for almost every industrial application and process.

Air-operated double-diaphragm (AODD) pumps for mining

Since 1955, Wilden has been the global leader in AODD pumps for use in a wide range of industries that rely on reliable, efficient, leak-free fluid- and small-solids-handling, including those found in the rapidly growing global mining industry.

After more than 50 years in the field, Wilden’s first AODD pump design, the Original™ Series, continues to set the standard in reliability in rugged operating conditions. These clamped pumps provide reliability without sacrificing ease of maintenance. Available in either metal (aluminum, stainless steel or ductile iron), plastic (polypropylene, PTFE) or PFA materials of construction, the Original Series metal pumps are offered in five sizes, from the 13mm (1/2in) PX1 to the 102mm (4in) PX20 models. All of these models can handle pressures up to 8.6 bar (125 psi), while they feature flow rates ranging from the PX1’s 62.8 lpm (16.6 gpm) to 1,211 lpm (320 gpm) for the PX20.

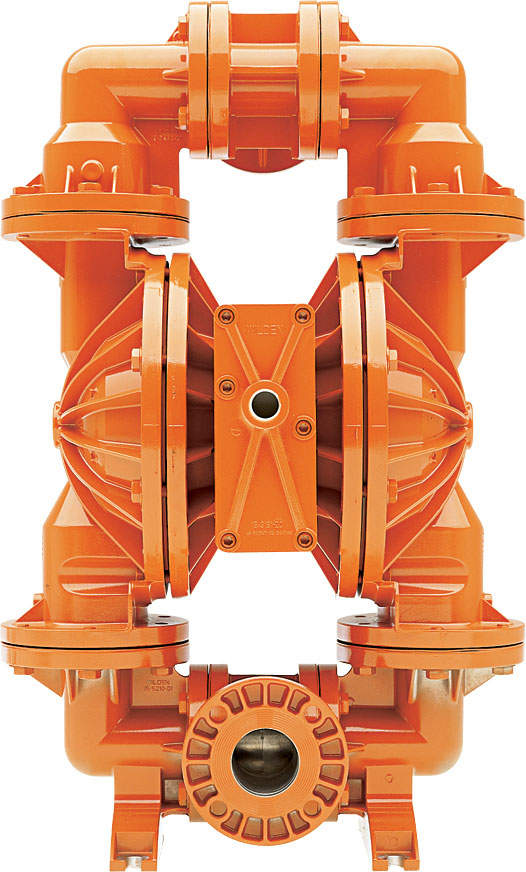

AODD bolted pumps

Wilden’s Advanced™ Series reigns as the global leader in AODD bolted pumps. Offered in a choice of aluminum, stainless steel, alloy-C, polypropylene, PVDF and PFA, Advanced Series metal and plastic pumps are specifically designed to deliver maximum performance, efficiency and containment.

The bolted configuration ensures total product containment, while the innovative liquid path reduces internal friction to maximize output and efficiency. Wilden Advanced Series metal pumps are available in five sizes from 6 mm to 76 mm (1/4in to 3in). Advanced Series Metal pumps feature flow rates to 1,021 lpm (270 gpm).

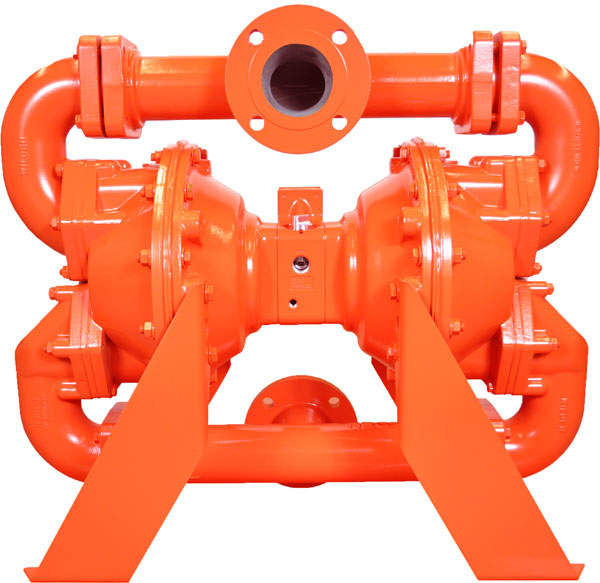

Pumps for transferring solid-laden slurries

Wilden’s Stallion® Series AODD pumps, a version of the Original Series, are designed to transfer solid-laden slurries safely and effectively. The pumps feature a large internal clearance and flow-through design that effectively keeps the pump from clogging.

Wilden’s Stallion pumps are available in three sizes: PX4, 38mm (1-1/2in), PX8, 51mm (2in) and PX15, 76mm (3in). All are available in either aluminum or ductile iron materials of construction, are submersible, intrinsically safe, lube-free, can run dry, have superior anti-freezing properties and can handle pressures of up to 125 psi. Depending on the model, flow rates range from 305 Ipm to 776 lpm (81 gpm to 205 gpm).

Wilden’s Brahma Series AODD pumps, a version of the Advanced Series, are designed to transfer large solids typical found in mining operations. The PX810 and PX1510 Brahma pumps include the Pro-Flo X™ ADS and are available in 51mm (2in) and 76mm (3in) center-ported styles. Brahma pumps offer DIN or ANSI connections, top inlet and bottom discharge and maximum operating pressures of up to 8.6 bar (125 psig).

AODD air-distribution systems for mining operations

The Original, Advanced, and Stallion AODD pumps all feature a version of Wilden’s patented Pro-Flo X™ air distribution system (ADS), which gives the user unprecedented operational flexibility. The Pro-Flo X features a patented efficiency management system (EMS™) that allows the user to easily optimize the ADS for any pump-size and to meet many application demands. For more information visit the company’s website, as listed in the contact details below.

Wilden AODD Pump Additional Benefits

Wilden air-operated double-diaphragm pumps have proven their durability and reliability in countless applications. Wilden pumps feature meticulously designed configurations to guarantee total pumped media containment and optimized internal liquid paths for reduced friction and maximized output and efficiency.

Elastomer materials are carefully chosen to provide maximum resistance to and minimize wear caused by abrasion, extreme temperatures, and harsh chemicals. Some of the benefits that Wilden pumps provide include:

|

|

|

|

|

|

|

Why Choose Wilden Diaphragm Pumps

As the inventors of the AODD pump, Wilden has pioneered countless innovations. Their state-of-the-art products are the most energy-efficient in the industry, and each pump is engineered to deliver a wide range of flow rates and outlet pressure levels for greater versatility.

Wilden has been an innovator and industry leader in air-operated double-diaphragm pump manufacturing for over sixty years. They manufacture a wide variety of pumps, all of which provide superior performance, unparalleled reliability, and the versatility to meet the needs of a range of industries and applications.

Superior craftsmanship and top-quality materials ensure that every Wilden pump, Liquid End Repair Kit, Air Section Repair Kit and Wilden Replacement Part will deliver years of worry-free operation with minimal maintenance requirements.

AODD & Diaphragm Pump Materials

Learn more about Wilden’s pump material options and featured pumps below. Not sure where to start? Feel free to contact us if you are unsure which pump you need and we can find a solution to your pumping needs.

Available AODD Pump Materials

- Die cast Aluminum

- Polypropylene

- PVDF

- Stainless steel

- Cast Iron

Available Diaphragm Materials

- Teflon®

- Wil-Flex™

- Polyurethane

- Saniflex™ (food grade elastomer)

- Buna-N

- Neoprene

- EPDM

- Viton

Wilden Diaphragm Pumps & AODD Pumps For Various Industries

There are a wide range of industries that require that their product be moved quickly and effectively without the fear of product breakdown or mishandling. Wilden positive displacement air-operated double-diaphragm pumps are trusted by top manufacturers across multiple industries and applications. Our AODD pumps can be found in virtually any industrial market, including but not limited to:

|

|

|

|

|

|

|

|

|

|

|

Featured Wilden Diaphragm & AODD Pumps

Wilden Pro-Flo® SHIFT Pumps

Wilden Pro-Flo® SHIFT pumps utilize a bolted design for superior product containment and are ATEX compliant. This pump is engineered for general industry and process applications where flow, efficiency and routine maintenance are required. SHIFT Series AODD pumps achieve up to 60% savings in air consumption and cost 50% less than electronically actuated ADS. Pro-Flo SHIFT pumps also deliver more yield per SCFM than competing AODD pumps.

Wilden Pro-Flo® Series AODD Pumps

This pump features only three moving parts for less downtime and simplified maintenance. These pumps run solely on compressed air and are pre-lubricated. Pro-Flo® Shift pumps can be used for submersible applications when using the Pro-Flo® SHIFT’s single-point exhaust option.

For fast installation, the Pro Flo Shift EZ Install Wil Flex utilizes a clamped-band design for easy assembly and disassembly and is ATEX compliant.

Wilden Stainless Steel/EZ Saniflex Pump

The Saniflo™ Hygienic™ Series pump meets the strict hygienic and sanitary requirements for the food-processing, pharmaceutical and biopharmaceutical industries. This FDA-approved pump utilizes a Tri-Clamp™ design for easy assembly and disassembly and is clean-in-place (CIP) capable.

Wilden Pumps is a well-known manufacturer of air-operated double diaphragm (AODD) pumps. These pumps are designed for transferring a wide variety of liquids, slurries, and viscous materials in industrial and commercial applications. They are popular for their versatility, reliability, and ability to handle harsh or hazardous materials in environments where other types of pumps might fail.

Here are some key features and uses of Wilden Pumps:

Key Features:

- Air-Operated: Wilden’s AODD pumps run on compressed air, making them energy-efficient and suitable for hazardous or explosive environments where electric motors may pose a risk.

- Diaphragm Design: The pump uses two diaphragms that alternately expand and contract to move fluid through the pump. This design is self-priming and can run dry without damaging the pump.

- Versatility: They are capable of handling a wide range of fluids, from thin liquids to thick slurries, and can also handle shear-sensitive fluids without causing degradation.

- Durability: Wilden pumps are built with tough materials that resist corrosion and wear, making them ideal for industries like chemical processing, food and beverage, mining, and pharmaceuticals.

- Easy Maintenance: Many models are designed for quick disassembly and repair, reducing downtime in critical operations.

- Bolted and Clamp Style: Wilden offers both bolted and clamped diaphragm pumps, providing flexibility depending on the needs of the user.

Common Applications:

- Chemical processing: Transporting aggressive or corrosive chemicals.

- Food and beverage: Pumping food products, sauces, or beverages without contamination.

- Mining: Moving slurry, sludge, or abrasive materials.

- Pharmaceutical: Handling sterile fluids or active ingredients.

- Water & wastewater: Pumping waste or sludge materials.

- Oil & gas: Used for oil transfer, frac fluid handling, and other industrial processes.

Advantages:

- No Electricity Required: Since Wilden pumps are air-driven, they can be used in explosive or hazardous environments where electric motors could be dangerous.

- Self-Priming: Can operate in dry conditions or on suction lifts, which eliminates the need for priming systems.

- Stall-Free: The pumps can run dry or at low flow rates without stalling, making them ideal for intermittent or variable flow applications.

Wilden is part of PSG (Process Solutions Group), a Dover company, which is a leading provider of pumps and other fluid transfer equipment.

If you have any specific questions about Wilden pumps or are looking for advice on choosing the right model, let me know!

Air Operated Double Diaphragm (AODD) Pumps are a type of positive displacement pump that uses compressed air to drive two diaphragms, which alternately move back and forth to pump liquids or slurries. These pumps are known for their versatility, reliability, and ability to handle a wide range of fluids, including those that are viscous, abrasive, or contain solids.

Key Features of AODD Pumps:

- Diaphragm Action:

- Two diaphragms are connected by a common shaft, and as one diaphragm moves forward, the other moves back. This creates suction and discharge cycles that move fluid through the pump.

- The diaphragms are typically made of materials like PTFE, rubber, or elastomers, chosen based on the fluid being pumped.

- Air Power:

- The pump operates using compressed air, making it suitable for hazardous environments (where electrical motors may pose a risk).

- The air-driven mechanism ensures that the pump can run dry without damage and can self-prime, meaning it can start pumping even if the suction line is empty.

- Self-Priming:

- AODD pumps can prime themselves, even with a high vertical suction lift, which means they don’t need to be manually primed or have an external priming system.

- Gentle on Fluids:

- AODD pumps are often used in applications where shear-sensitive fluids (such as food products or chemicals) are handled. The diaphragm’s gentle, non-pulsating movement reduces the risk of damaging delicate products.

- Adjustable Flow:

- The flow rate of an AODD pump is controlled by adjusting the air pressure. Increasing the air pressure increases the flow rate, while reducing it slows down the pump.

- Versatile Fluid Handling:

- AODD pumps are capable of handling a wide range of fluids, including liquids, slurries, and liquids with high solid content.

- They are commonly used in industries such as chemical, pharmaceutical, food & beverage, mining, wastewater, and agriculture.

Advantages:

- No electricity required: Because they are powered by compressed air, they are ideal for hazardous or explosive environments where electric motors would be unsafe.

- Portability: These pumps are often compact and portable, making them ideal for use in locations where mobility is important.

- Dry Run Capability: AODD pumps can operate without fluid and will not be damaged by running dry, unlike many other pump types.

- Variable Flow: The flow rate is easily adjustable by regulating the compressed air pressure.

- Durable Construction: They are available in corrosion-resistant materials like stainless steel, plastic, or aluminum, making them suitable for aggressive or corrosive fluids.

Common Applications:

- Chemical Transfer: AODD pumps are used for transferring a wide range of chemicals, including acids, solvents, and viscous liquids.

- Food & Beverage Processing: For pumping food-grade liquids like juices, sauces, and syrups, as well as slurries in food processing.

- Mining & Slurry Handling: These pumps are widely used in mining applications to handle abrasive slurries and sludges.

- Pharmaceutical Manufacturing: AODD pumps can transfer sensitive chemicals without contamination.

- Wastewater Treatment: AODD pumps are used to move sludge, chemicals, or other wastewater treatment materials.

Disadvantages:

- Noise: Air-operated pumps can be noisy due to the air pressure required to operate them.

- Air Consumption: These pumps can consume a significant amount of compressed air, which may require a large or continuous supply of air.

- Flow Pulsation: While generally more stable than some pumps, AODD pumps can create some level of pulsation in the flow, which may not be ideal for all applications.

How They Work (In Detail):

- Air Valve Mechanism: The core of the AODD pump is the air valve that alternates the direction of airflow to the diaphragms. When one diaphragm moves forward, it compresses the air on one side, creating suction on the other side of the diaphragm to draw in fluid. When the diaphragm moves back, it expels the fluid.

- Pumping Cycle:

- Suction Stroke: The diaphragm moves backward, creating a vacuum that pulls the fluid into the chamber.

- Discharge Stroke: The diaphragm moves forward, forcing the fluid out of the discharge port under pressure.

AODD pumps are highly customizable and can be fitted with different diaphragms, valves, and materials to suit specific fluid characteristics, ensuring versatility in various applications.