Description

Conductivity Control System

ENGINEERIC is the Supplier and manufacturer of conductivity control systems in Pakistan.

Controller Range

A Conductivity Controller is designed to work as an automated device to control external devices based on the measured Conductivity value. Our Conductivity controllers offer a range of control options and are available in a number of different configurations including Surface Mounted Conductivity Controller configuration and as a Panel Mounted Conductivity controller configuration.

Our range of Conductivity Controllers/conductivity control systems is all able to work with a range of conductivity cells and with a range of cell constants (K values), with or without temperature compensation.

All of our Conductivity controllers are able to measure across a range of conductivity values, with many offering auto-ranging or manual ranging across the desired range.

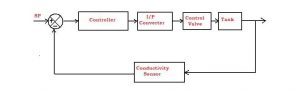

Conductivity Control System (Measurement and Control).

The Conductivity controllers offer a number of different control options which can include on / off control relays, PID Control, as well as expandable 4-20mA signal transmission. These output signals are often used in combination with dosing pumps, solenoid valves and actuated positioning valves to ensure precise control based on the conductivity value.

Conductivity Control System Construction

-

The conductivity control system mainly consists of an electrolytic tank.

-

The electrodes(sensor) are placed in the tank, which senses the conductivity.

-

The electrodes are connected to the transmitter through the cable wire.

-

The transmitter is connected to the controller, which controls the control valve.

-

The controller is connected to the control valve.

WORKING

If the level of the tank is increased above the setpoint value, that level will be sensed by the electrodes(sensor). Then the conductivity of the liquid is converted into an electrical signal. That signal is processed to the transmitter for the amplification purpose.

That amplified signal is further processed to the controller, where the present signal is measured and compared with the setpoint value. Then the control valve will be closed and the conductivity level is decreased through the outlet pipe until the conductivity reaches near the setpoint value.

If the level of the tank is decreased below the setpoint value, that level will be sensed by the electrodes(sensor). Then the conductivity of the liquid is converted into an electrical signal. That signal is processed to the transmitter for amplification purposes.

That amplified signal is further processed to the controller, where the present signal is measured and compared with the setpoint value. Then the control valve will be opened and more electrolyte solution will be filled in the tank so as to increase the conductivity of the liquid.

Resistivity Controller

In addition to our conductivity controller range, we also offer a resistivity controller. This device is designed for measuring solutions with exceptionally low conductivity values.

Our resistivity controller is able to offer the measured value in either the SI unit of nS (nano-siemens) or the SI unit of Resistance in Meg-Ohms (MΩ) depending on whether we’re measuring the solutions conductance or the resistance of the solution.

Designed to offer the highest possible accuracy of the solutions conductivity or resistivity our resistivity controller uses a derived look-up table to accurately compensate the solutions measurement value against the measured temperature.

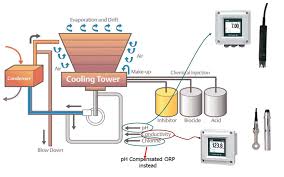

Measuring the Electric Conductivity with Clean-in-Place (CIP) System

In the Pharmaceutical, Chemical, and Food & Beverage industries, after manufacturing products, the cleaning and sterilization of tanks and piping are done with various cleaning solutions, fresh or hot water, and steam. Clean-in-Place (CIP) is a system designed for automatic cleaning and disinfecting.

Electrodeless conductivity control systems

Electrodeless conductivity control systems are free of problems associated with fouling because no part of the sensor directly contacts the rinse water. A nonconductive plastic casing surrounds two wire loops that induce and detect a current, which is proportional to conductivity.