Agitator and Mixers

An Agitator is a machine used in a tank for mixing various process media together. Media include all liquid types, gases & solids (such as salts, powders, granules etc). In summary, it works by rotating an impeller to impart energy to the media which interact and mix. The components of an agitator in general are the motor & gearbox, shaft & impellers selected for the duty.

What is the purpose of an agitator?

An Agitator is used for mixing different process media – liquids, gases and solids in chemical addition or Pharmaceutical Ingredients. The agitator imparts energy through mechanical mean by rotating a shaft on which there is an impeller designed specifically for the duty. This could be axial pumping, gas induction, flocculating, high viscosity products, high & low shear mixing etc. An agitator is also used in the Water Industry for adding various chemicals to bring the source water up to drinking water standards

What are the various parts or components of an agitator?

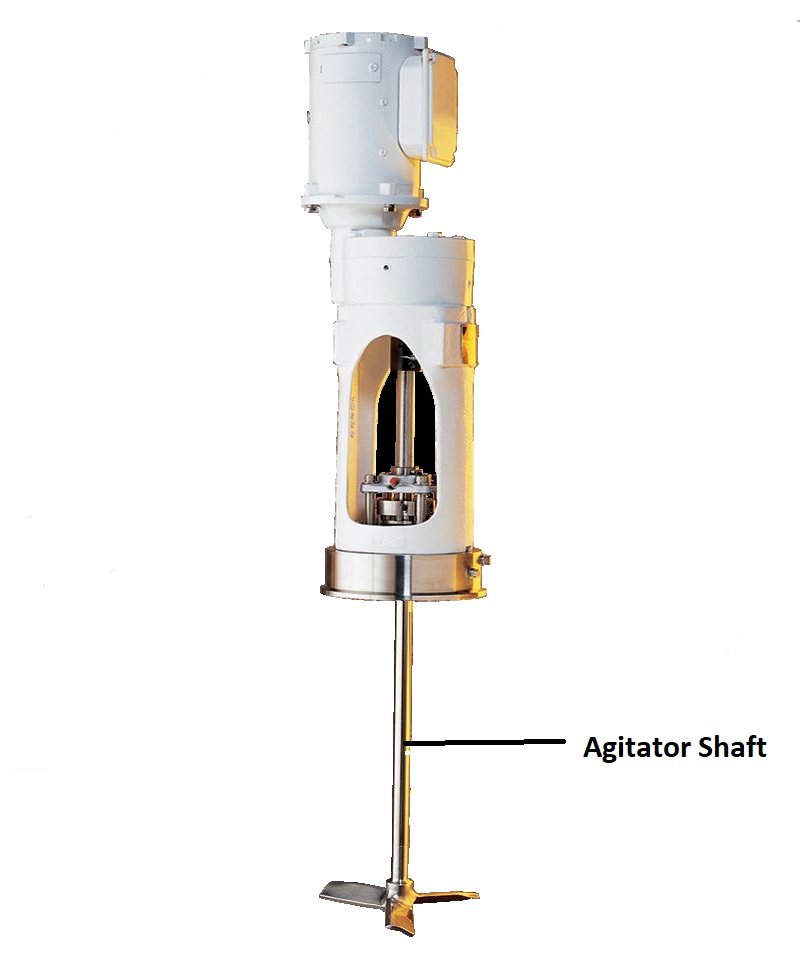

An Agitator is generally made up of a three main components – a shaft with impellers, a mechanical seal and motor with option of gearbox for lower RPM duties.

The agitator is mounted onto the vessel or via a supporting bridge in the water industry. The mechanical seal has a number of options depending on the duty – single/double mechanical seal, dry or wet mechanical seal, gas lift off mechanical seal that is related to the duty involved.

An agitator shaft is connected to the drive unit (motor & gearbox) and where the impellers used for the mixing are welded or bolted onto. There are options for magnetic driven units where there is a hermetic seal as opposed to mechanical.

What are the different types of agitators and their selection criteria?

Agitators can be simplified into Bottom Entry Agitator, Side Entry Agitator and Top entry Agitator depending on the duty & scale of the application to be mixed.

90% of Agitators are a Top Entry Agitator in API / Chemical / Water industries. The main advantages of a Top Entry Agitator is that it can handle a larger variance in viscosities and specific gravities and also the fact that the mechanical seal is not in the liquid.

The remaining 10% include Bottom Entry Agitator, Side Entry Agitator and Bottom Entry Mag Drive Agitator. Milk silos & very large holding tanks use side entry agitators not necessarily for mixing but to keep the process media moving and keep the milk cool while bottom entry agitators are more common in the Biotechnology sector, where it is a magnetic driven unit (see below).

The applications for a Magnetic Drive Agitator generally fall under the following main headers (but is not limited to):

- Blending

- Heat transfer

- Homogenisation

- Reactor

- Suspension

- Storage

- Continuous reaction

- Fermentation

- Hydrogenation

Depending on the industrial sector the customer is in, the mechanical & material suitability for each application can differ greatly. Each of the applications have a typical impeller type that is suited to deliver the turbulence necessary to mix the ingredients.

TANK AGITATORS AND MIXERS

For over five decades, ProQuip has provided innovative, high performance tank agitators and mixing solutions around the globe from the low shear requirements of bioprocess to the strain of high temperature, high pressure polymerization reactors. We use our extensive knowledge of mixing technology and expert in house engineering to design and manufacture trouble free, cost effective bottom, side , and top entry tank agitators that meet your specific process needs including:.

- It performs the job you need it to do

- It operates economically, reliably, and efficiently

- It is easy to service and maintain

- It is fully supported by the manufacturer throughout its lifecycle

Committed to Meeting Your Unique Tank Agitator and Mixer

- Wide Horsepower Range from fractional to over 1,000 HP

- High Torque Values up to 1,000,000 IN-LBS

- High Quality Components specifically designed for years of continuous mixing service

- Simple Mechanical Designs for easy installation, operation and maintenance

- In-house Testing and evaluation of mixing applications

- Personalized Service including expert support throughout the product lifecycle