Description

Peristaltic Pumps in Pakistan

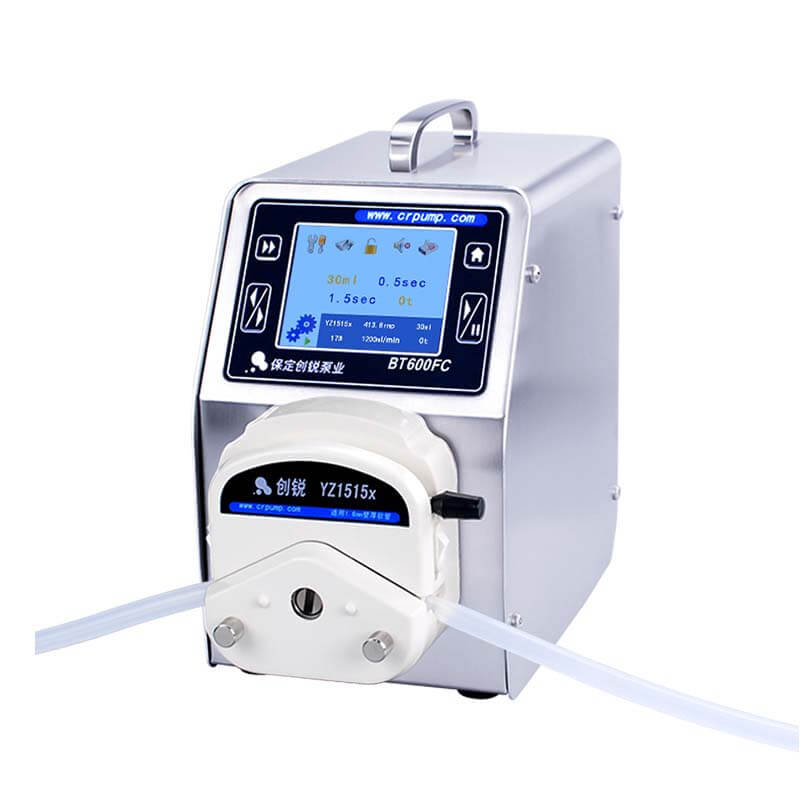

A peristaltic pump, also commonly known as a roller pump, is a type of positive displacement pump used for pumping a variety of fluids. The fluid is contained in a flexible tube fitted inside a circular pump casing.

Peristaltic Pumps in Pakistan

Additionally, as the tube opens to its natural state after the rollers pass, more fluid is drawn into the tube.

The body of fluid is transported through the tube, toward the pump outlet. Peristaltic pumps may run continuously, or they may be indexed through partial revolutions to deliver smaller amounts of fluid.

ENGINEERIC is the distributor of Peristaltic pumps in Pakistan.

Peristaltic Pumps in Pakistan

What Are The Benefits Of Peristaltic Pumps Technology?

- Dry running

- Self-priming

- Reversible (DC)

- Flow regulation

- Excellent for use with viscous or aggressive media

- Tolerant to contamination with particles

- ENGINEERIC Peristaltic pumps in Pakistan offer flow rates up to 2000 ml/min, suction height up to 9 m H2O, pressure height up to 100 m H2O

What Makes ENGINEERIC Peristaltic Pumps Stand Out?

The ENGINEERIC offers pumps with flow rates ranging from smaller than 0.1 ml per minute up to 2000 ml per minute. In special product versions, high pressure of up to 10 bar can be handled. Our wide portfolio provides solutions for even the most demanding liquid handling applications.

| Sr# | Description | Range (From) | Range (To) |

| 1 | Flow rates ranging | 0.1 ml/m | 2000 ml/m |

What Are The Peristaltic Pump Motor Types?

Common motor types for peristaltic pumps include brushed direct current (DC), brushless direct current (BLDC), alternating current (AC), or stepper motors.

Peristaltic Pumps in Pakistan

What is a peristaltic pump used for?

Peristaltic hose pumps can transfer, dose or meter a range of fluids, including cosmetic lotions, abrasive slurries such as lime milk in mining applications, or sodium hypochlorite at water treatment plants.

Peristaltic pumps offer a flexible solution for chemical processing, wastewater applications, food & beverage and more. When paired with variable speed drives or a PLC, pump flow can be adjusted to accurately meter or dose fluids.

Albin Pump offers a wide range of pumps that can be configured to meet your fluid transfer needs, regardless of industry.

How does a peristaltic pump work?

Once the pumped liquid has entered the hose, the second roller passes over the hose. This motion pushes the liquid toward the pump outlet. As the shoes are rotated, the hose section that was compressed begins to rebound to its nominal state, creating a vacuum that pulls fluid into the hose.

When the shoe at the discharge side is detached from the hose, the opposing shoe is already compressed. This arrangement prevents any backflow. The pumped fluid is then successfully pulled in and pushed out due to the wheel rotation.

How to control a peristaltic pump

Peristaltic pumps are built with a specific motor, reducer and pump head designed to perform at a certain flow rate and pressure. This simple design allows you to control the pump in a variety of ways. A simple way to control your peristaltic pump is with line start on/off controls. If you require more control, the peristaltic pump can be controlled through a PLC.

Peristaltic Pumps in Pakistan

The peristaltic pump is an electric pump. For an even more superior level of control, it can be connected to a VFD (variable frequency drive) control to manipulate speeds.

Peristaltic Pumps in Pakistan

Peristaltic Pump Advantages

- Peristaltic pumps have fewer mechanical parts than other pump technologies, decreasing the service required for worn parts.

When needed, pump maintenance is quick and easy. Scheduled service consists of a simple hose change-out, yielding a lower total cost of ownership than many other pump technologies.

- Fluid does not touch any part of the pump, except the inner surface of the hose or tube and the connectors.

- The rollers or shoes move fluid through the hose or tube, so there is no need for degassing valves. The rollers squeeze the tube to prevent backflow and eliminate the need for mechanical seals, creating a seal-less system.

- Flow can occur in either direction through the hose. This bi-directional flow enables a user to easily clean the hose by flushing the lines and the process piping system during a purge cycle.

- Peristaltic pumps are designed to run dry, self-prime, and offer a high suction lift (32 ft / 9.8 m). Their sealless construction uses no mechanical seals or stuffing boxes, which can lead to fluid leaks.

- Peristaltic pumps are easy to set up, operate and maintain without specialized training. These positive displacement pumps do not require compressed air or rely on valves that can clog. The peristaltic pumping action is ideal for handling abrasive fluids and shear-sensitive fluids.